COBRA CONSTANTLY IMPROVING WITH LATEST TECHNOLOGY

|

Fully digital proportional controls for fast, precise and smooth operation. Digital processor providing self diagnostics and quick settings. New patented anti-two-block system that does not require bulky cable reel and end of boom micro-switch. 4400 cranes now available in 16′ & 20′ with 2 hydraulic boom extensions. |

|

COBRA MECHANIC SERVICE CRANES ARE ENGINEERED FOR A WORKING LIFE OF 15 YEARS

Cobra service cranes have been built since 1996 and have a proven track record operating in the high temperatures of the Australian desert, to the coldest conditions of Northern Canada.

Click here to see an average day in the life of a Cobra 5500 in winter conditions.

Boom

The boom is constructed of one piece of high tensile, Domax steel with a single robot-made weld. This, combined with the famous hexagonal shape, gives the boom exceptional strength and structural integrity.

The boom is constructed of one piece of high tensile, Domax steel with a single robot-made weld. This, combined with the famous hexagonal shape, gives the boom exceptional strength and structural integrity.- The Cobra crane weighs less than that of any other manufacturer.

- Internal hydraulic extension cylinders on all units with double extensions for protection.

- Low friction, high strength anti-wear techno polymer weather proof pulley.

- New patented anti-two-block system that does not require bulky cable reel or microswitch.

- Pre-drilled holes for work lights.

Winch

- Hydraulic high speed/high efficiency planetary winch with integrated high precision hydraulic brake.

- High tensile strength non-rotating cable.

- Winch line pull limiter.

- Spring loaded cable pressure roller standard on 11000 & 12000 (optional accessory on the 5500, 6600 & 8000 crane models).

Travelling Block

- 2 part block for double pull line standard (optional counterweight for single line pull).

- New design auto-release hook for traveling block (optional spring safety latch).

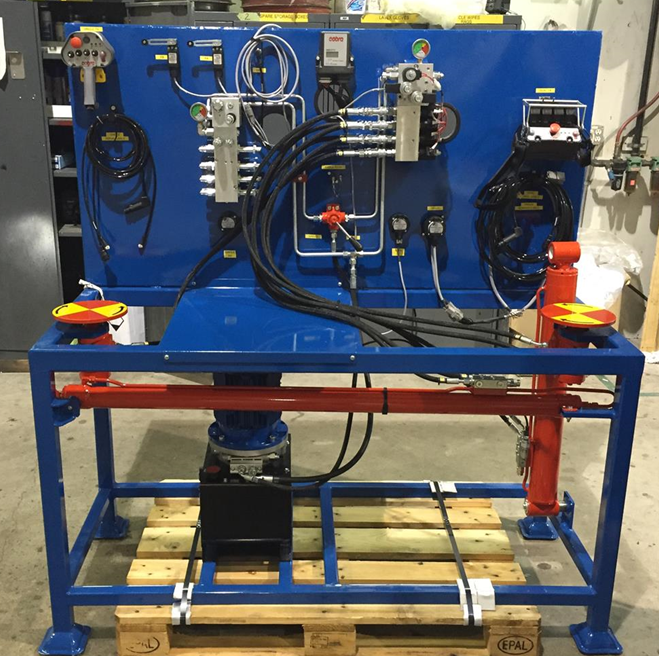

Hydraulic System

- Single proportional or dual proportional control valve available on all models.

- Proportional manual overrides on all functions.

Drive system

- Standard digital remote control unit (worldwide 2,4 GHz frequency) transmitter handset

(available in two different versions):- Single-hand transmitter (IP56 waterproof for proportional mono-function system) with integrated feedback LEDs for loading percentage monitoring (complying with EN12999/AS1418 norms) and equipped with standard & optional functions selectors.

- Belly-box paddle-type transmitter (IP56 waterproof for proportional mono & multi-function systems) with integrated feedback LEDs for loading percentage monitoring (complying with EN12999/AS1418 standards) and equipped with standard & optional functions selectors.

- ’2G4 standard receiver (IP67 waterproof placed on the crane column) managing the following signals:

- Rated capacity limit.

- Winch pull limit.

- Winch drop stop.

- Work light on / off.

- Machine Management System” (MMS) box IP67 waterproof connected via CAN-BUS cable to the receiver with integrated LED display for:

- Crane status monitoring.

- Self-diagnostics crane setting procedures.

- Equipped with power wires for work light.

Additional Options

“TRAUX” auxiliary functions receiver (IP67 waterproof placed on the vehicle) managing the following optional signals (received from the transmitter and sent to the different outputs with the exception of the SCU signal sent to the MMS

unit via the “CAN-BUS” cable of the standard “2G4” receiver)

- Vehicle engine start/stop.

- Vehicle engine RPM.

- Air compressor start/stop.

- Horn activation.

Support

- Dealer network trained and supported by factory trained technicians.

- Factory trained technicians on hand to assist dealer network or end users.

- Latest test equipment to test all crane functions.

- Large inventory of parts.